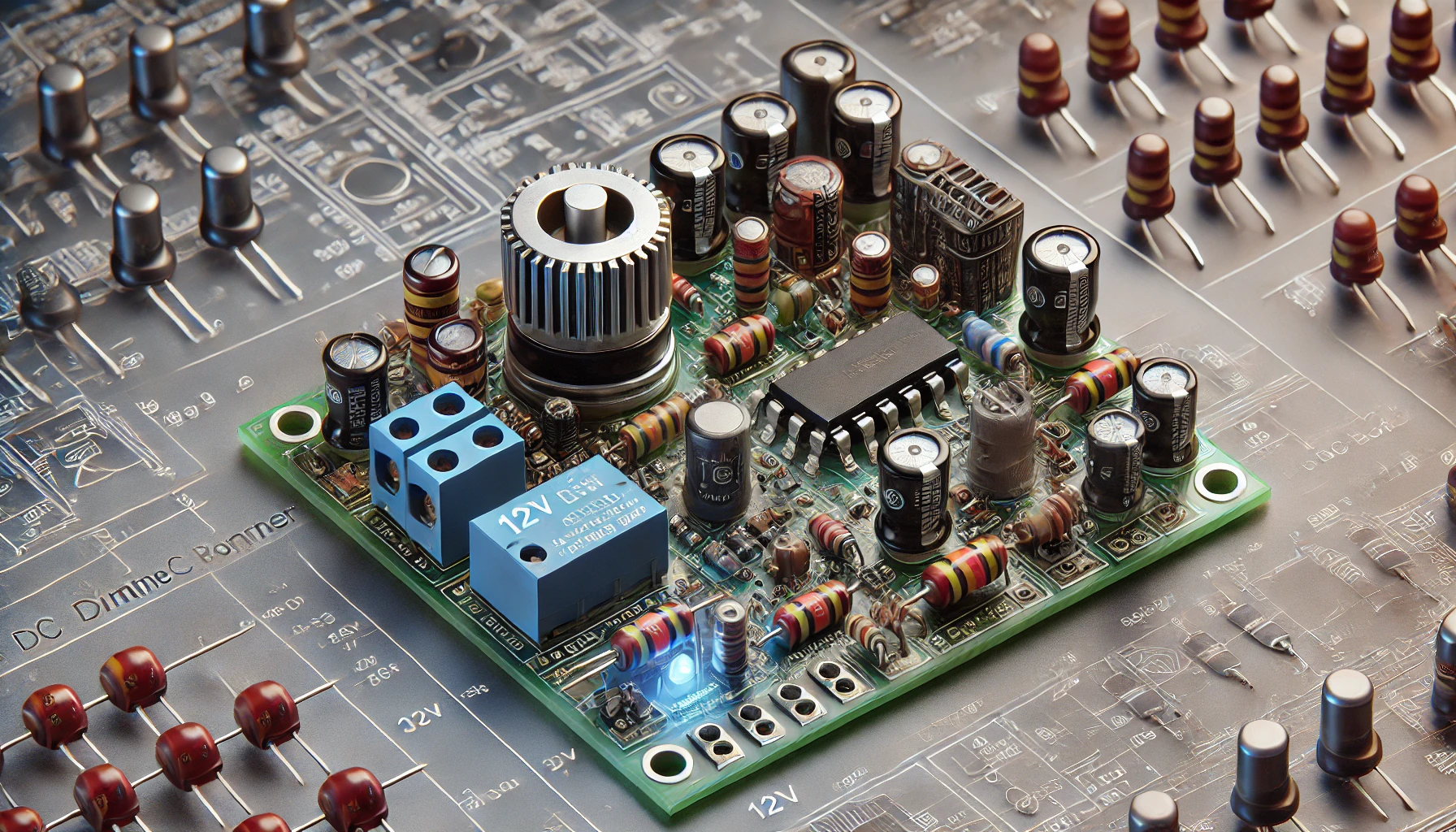

Build a DC Dimmer Precise Control for Motors & LEDs with Full Schematic and PCB , If you’ve ever worked on a project involving DC motors or LED lighting, you know that controlling the brightness or speed precisely can be challenging without a suitable control mechanism. This article provides a step-by-step guide on building a DC dimmer to achieve smooth, adjustable control for these devices. We’ll cover the components, schematic, and PCB layout, and discuss the nuances of assembly and operation.

Introduction: Why Use a DC Dimmer?

DC dimmers are valuable in various applications because they allow fine control over DC devices, such as motors and LEDs, which are common in robotics, automotive systems, lighting, and home automation. Traditional methods, like resistive dimming, can lead to inefficiency and heat buildup. A MOSFET-based DC dimmer, however, uses electronic switching to manage current flow, reducing power loss and offering precise control over the output.

Project Overview

This project leverages the IRFP260 MOSFET to act as a switch for controlling current. The IRFP260 is a robust field-effect transistor capable of handling high currents, making it ideal for projects with significant power requirements. To ensure the MOSFET operates reliably, we use a 200-ohm resistor (R1) and a 47k-ohm resistor (R2) to manage the gate voltage. These components are key to protecting and controlling the MOSFET’s state, ensuring smooth dimming without abrupt changes in performance.

Components Needed

- IRFP260 MOSFET: Acts as the main switching element in the circuit.

- 200-ohm Resistor (R1): Pull-up resistor for the MOSFET gate.

- 47k-ohm Resistor (R2): Limits the current to the gate.

- 50k-ohm Potentiometer: Allows for adjustment of the gate voltage, controlling current flow and dimming level.

- PCB and Connector Terminals: For stable connections and ease of assembly.

- Heat Sink: Essential for dissipating heat from the MOSFET during prolonged use.

Circuit Schematic and Working Principle

The circuit operates by adjusting the voltage applied to the MOSFET gate. Here’s how it works:

- MOSFET Switching: The IRFP260 MOSFET acts as a controlled switch, adjusting current flow based on the gate voltage. When more voltage is applied to the gate, the resistance between the MOSFET’s drain and source decreases, allowing more current to pass through to the load (motor or LED).

- Resistor Functions: R1 serves as a pull-up resistor, ensuring the MOSFET remains off when the gate voltage is low, while R2 limits current to the gate.

- Potentiometer Control: The 50k potentiometer lets you vary the gate voltage, adjusting the amount of current that flows through the MOSFET. This control translates into changes in brightness (for LEDs) or speed (for motors).

PCB Design

For a clean and reliable setup, the circuit is mounted on a PCB. The design includes terminals for input and output connections, and space for each component. The compact arrangement minimizes wire connections, reducing potential issues with interference or signal loss. You can download the PCB files or use online resources to order a custom design.

Assembly Process

- Mount Small Components First: Begin with the smaller resistors (R1 and R2) to create a stable base.

- Add Larger Components: Attach the MOSFET and potentiometer, ensuring they are secured firmly.

- Heat Sink Installation: Since the MOSFET will handle significant current, it’s important to attach a heat sink to prevent overheating.

- Check Connections: Before powering up, inspect all soldered joints to ensure no loose or shorted connections.

Testing the DC Dimmer

Once assembled, connect a 12V DC power supply to the input terminal and a small DC motor or LED to the output. With the power on, turn the potentiometer to adjust the gate voltage. As you vary the potentiometer:

- Motor Speed Control: Observe the speed of the motor change proportionally to the potentiometer adjustment.

- LED Brightness Control: For LEDs, adjust brightness by regulating the current with the potentiometer.

For an additional layer of verification, connect a multimeter to monitor current flow and ensure the dimmer operates within the desired range. Remember to test the device under different loads to confirm stability.

Troubleshooting Common Issues

- Overheating MOSFET: This typically occurs if there is insufficient cooling. Always add a heat sink, and avoid prolonged high-current operation without adequate ventilation.

- Inconsistent Dimming Response: Double-check resistor values and potentiometer connections. Incorrect values or poor connections can cause unstable dimming.

- Short Circuit or No Response: Reinspect all solder joints and connections. A misplaced component or faulty solder joint can disrupt the circuit.

Future Enhancements: PWM Control

This DC dimmer operates on direct current control, but further precision can be achieved with PWM (Pulse Width Modulation) control, allowing rapid switching at controlled intervals. PWM-based dimmers minimize heat buildup and improve efficiency, making them ideal for battery-operated or portable devices.

Conclusion

This DC dimmer circuit provides a straightforward yet efficient way to control motors and LEDs with a high level of accuracy. Whether you’re a hobbyist working on a DIY project or an engineer needing precise DC control, this design offers a reliable solution. With the right components and careful assembly, you can adjust output to your exact needs, achieving optimal performance for your DC devices.

Build a DC Dimmer Precise Control for Motors & LEDs with Full Schematic and PCB

Video link Build a DC Dimmer Precise Control for Motors & LEDs with Full Schematic and PCB

Comments (0)